Compressed gas cylinder hydraulic burst testing machine

The compressed gas cylinder hydraulic burst testing machine is a device specifically designed to test the safety and pressure resistance of high-pressure gas cylinders. Through water pressure explosion test, the bearing capacity of gas cylinders under high pressure conditions and the pressure during explosion can be determined. This type of test is mainly used to detect the production quality of gas cylinders and ensure their safety during use. It is widely used in the testing of various high-pressure containers such as liquefied gas cylinders, oxygen cylinders, carbon dioxide cylinders, and fire gas cylinders. The compressed gas cylinder hydraulic burst testing machine is a device specifically designed to test the safety and pressure resistance of high-pressure gas cylinders. Through water pressure explosion test, the bearing capacity of gas cylinders under high pressure conditions and the pressure during explosion can be determined. This type of test is mainly used to detect the production quality of gas cylinders and ensure their safety during use. It is widely used in the testing of various high-pressure containers such as liquefied gas cylinders, oxygen cylinders, carbon dioxide cylinders, and fire gas cylinders.

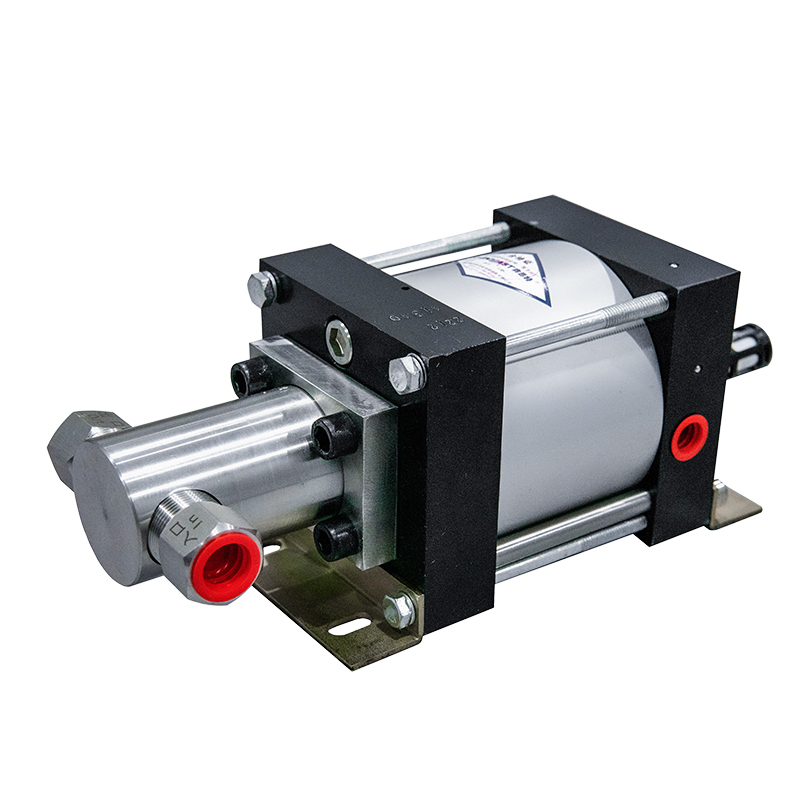

The hydraulic blasting test machine mainly relies on an internal liquid booster pump to achieve the required pressure for testing and complete the inspection. Its main functions and components are as follows.

Liquid booster pump: used to inject water into the interior and gradually increase the pressure to the set value, usually with a pressure capacity of several tens of MPa.

Water pressure transmission system: using water medium to transmit pressure to ensure uniform, stable, and safe pressure. Water is more suitable as a transmission medium than gas because it is incompressible and can effectively avoid the impact danger caused by gas explosions.

Experimental control system: used to set pressurization parameters, monitor the pressure of gas cylinders in real time, and record pressure data during blasting.

Pressure sensor: used for precise measurement and display of various pressures in the system.

Safety protection device: The testing process may cause the gas cylinder to burst, and the testing machine is generally equipped with a sturdy protective cover to prevent the fragments generated during the blasting process from causing harm to personnel.

Fixtures and fixing devices: used to firmly fix the gas cylinder in the testing position, ensuring the stability and accuracy of the testing process.

When testing gas cylinders, the first step is to conduct an external inspection to ensure that there is no obvious damage or defect, and then connect the gas cylinder to the hydraulic burst testing machine. Inject water into the cylinder to ensure that there is no air residue inside, and then gradually increase the internal pressure through a water pump until the design pressure limit of the cylinder is reached. Continue to apply pressure until the gas cylinder bursts, at which point record the burst pressure value of the gas cylinder to evaluate its pressure resistance limit. After the experiment is completed, analyze the difference between the burst pressure and the expected design value to determine whether the gas cylinder meets the standard requirements.

Gas cylinders are subjected to extremely high pressure in the working environment, and their safety can be evaluated through explosion tests to prevent danger caused by cylinder explosions. Manufacturers can use this equipment to conduct random inspections on the gas cylinders they produce, ensuring that the products leaving the factory comply with national and industry standards. New gas cylinder materials or designed gas cylinders must undergo a burst test to verify their safety performance before being put into use. The hydraulic blasting test machine can be widely used in the manufacturing, testing, and certification of gas cylinders in industries such as industry, medical, chemical, and firefighting.

The hydraulic blasting test machine mainly relies on an internal liquid booster pump to achieve the required pressure for testing and complete the inspection. Its main functions and components are as follows.

Liquid booster pump: used to inject water into the interior and gradually increase the pressure to the set value, usually with a pressure capacity of several tens of MPa.

Water pressure transmission system: using water medium to transmit pressure to ensure uniform, stable, and safe pressure. Water is more suitable as a transmission medium than gas because it is incompressible and can effectively avoid the impact danger caused by gas explosions.

Experimental control system: used to set pressurization parameters, monitor the pressure of gas cylinders in real time, and record pressure data during blasting.

Pressure sensor: used for precise measurement and display of various pressures in the system.

Safety protection device: The testing process may cause the gas cylinder to burst, and the testing machine is generally equipped with a sturdy protective cover to prevent the fragments generated during the blasting process from causing harm to personnel.

Fixtures and fixing devices: used to firmly fix the gas cylinder in the testing position, ensuring the stability and accuracy of the testing process.

When testing gas cylinders, the first step is to conduct an external inspection to ensure that there is no obvious damage or defect, and then connect the gas cylinder to the hydraulic burst testing machine. Inject water into the cylinder to ensure that there is no air residue inside, and then gradually increase the internal pressure through a water pump until the design pressure limit of the cylinder is reached. Continue to apply pressure until the gas cylinder bursts, at which point record the burst pressure value of the gas cylinder to evaluate its pressure resistance limit. After the experiment is completed, analyze the difference between the burst pressure and the expected design value to determine whether the gas cylinder meets the standard requirements.

Gas cylinders are subjected to extremely high pressure in the working environment, and their safety can be evaluated through explosion tests to prevent danger caused by cylinder explosions. Manufacturers can use this equipment to conduct random inspections on the gas cylinders they produce, ensuring that the products leaving the factory comply with national and industry standards. New gas cylinder materials or designed gas cylinders must undergo a burst test to verify their safety performance before being put into use. The hydraulic blasting test machine can be widely used in the manufacturing, testing, and certification of gas cylinders in industries such as industry, medical, chemical, and firefighting.

previous page:Banco de pruebas de hermeticidad de válvulas

CONTÁCTENOS

Utilice el siguiente formulario para ponerse en contacto.

Si necesita una respuesta nos pondremos en contacto lo antes posible.